ADVANCED

MANUFACTURING

| R&D leveraging UMaine’s expertise in forest-derived bio-composites with the world’s largest thermoplastics 3D printer to drive the future of advanced manufacturing with applications in marine, defense, housing, renewable energy, and transportation industries.

ADVANCED MANUFACTURING

R&D leveraging UMaine’s expertise in forest-derived bio-composites with the world’s largest thermoplastics 3D printer to drive the future of advanced manufacturing with applications in marine, defense, housing, renewable energy, and transportation industries.

Large-Scale & Bio-Based

Additive Manufacturing

For more than 25 years, the ASCC has been on the cutting edge of bio-based composites made with Maine wood products and is developing bio-based, renewable feedstocks using cellulose nanofibrils for additive manufacturing. Adopting the low cost of bio-derived and bio-filled feedstocks for use in additive manufacturing will pave the way for reducing manufacturing costs with partner industries looking to utilize this technology.

Additive Manufacturing Research

BioHome3D

BioHome3D is the first 3D-printed house made entirely with bio-based, wood residual, and recyclable materials that are designed to address labor shortages and supply chain issues driving high costs and constricting the supply of affordable housing.

SM²ART

The SM²ART Program is a research collaboration between the University of Maine and Oak Ridge National Laboratory. The partnership advances 3D printing with wood products, creating a new market for Maine’s forest products industry, an industry that has been the backbone of Maine’s economy for generations.

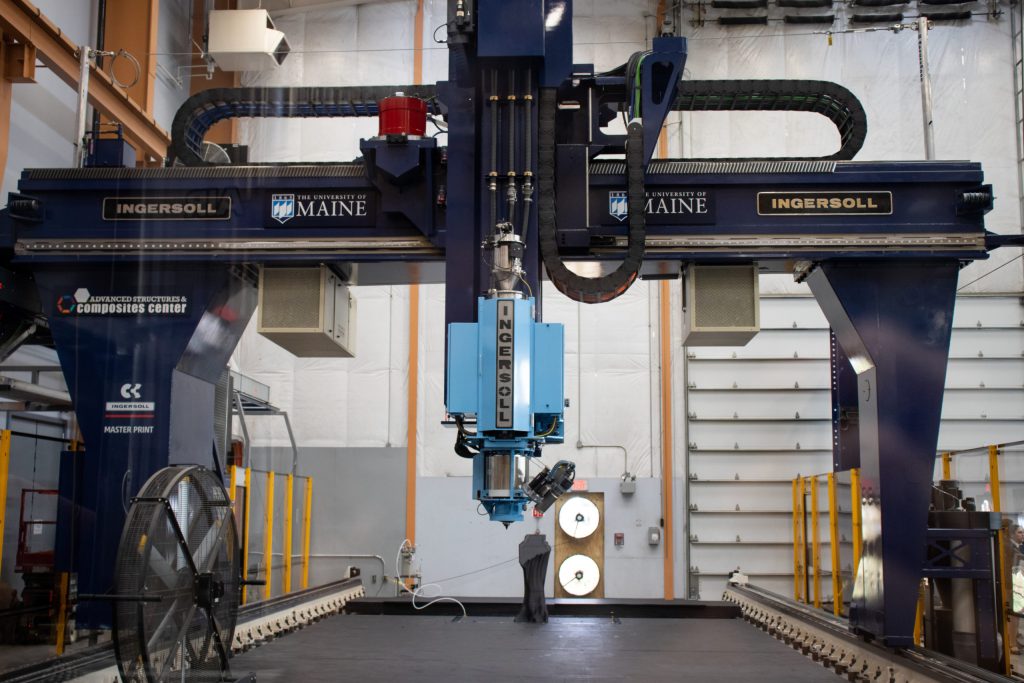

Ingersoll: MasterPrint

The Ingersoll MasterPrint, the worlds largest thermoplastics 3D printer, has enabled groundbreaking advances in large-scale additive manufacturing, including 3Dirigo and BioHome3D.

Accelerating Rapid Prototype (ARP)

The goal of the ARP program is to optimize the design and enhance the quality of 3D printed parts in order to move towards “born certified” printed parts. To accomplish this goal, the ASCC will link high-performance computing, sensor integration, and AI to create ‘smart’ printers that can adjust prints in real-time to improve performance and the quality of parts produced using the world’s largest 3D printer. The printer will be enhanced with an extruder capable of depositing materials at 500 lbs/hour, continuous fiber deposition capabilities, and state-of-the-art sensors to transform additive manufacturing using AI.

3Dirigo

3Dirigo has two Guinness World Records:

1. World’s largest 3D printed boat

2. World’s largest 3D printed object.

Large-Scale & Bio-Based

Modeling & Design

The MD&S team leads research in developing and applying modeling methods for composite manufacturing processes and performance modeling of structures, focusing on enhancing engineering tools. Their responsibilities include researching advanced manufacturing processes (additive, subtractive, AFP, hybrid), developing analysis methods and design workflows, and designing evaluation structures for tool calibration and validation. The team emphasizes naval architecture, integrating Navy software design tools, and improving vessel structural and system design.

A significant focus is the design and engineering of maritime structures using advanced composite manufacturing processes. The team conducts predictive analyses supporting Industry 4.0 and utilizes digital manufacturing tools for modeling and simulation. Their core competencies include numerical modeling (thermal, structural, CFD), manufacturing process modeling, multi-scale modeling, and developing material models and vessel design packages. These efforts ensure the effective application of advanced composites in maritime structural engineering.

Automation & AI

The ATSAI team focuses on enabling and accelerating data-driven manufacturing research across various materials, processes, and emerging technologies. By developing new Industry 4.0+ software capabilities in the Industrial Internet of Things (IIoT), data engineering, and AI-enabled data science, the team aims to revolutionize the manufacturing landscape. Key focus areas include simulation and design tools that enhance advanced manufacturing processes, such as anisotropic material simulation and optimization, cost optimization tools, and the BIM2LAAM compiler for architecture-to-Large Area Additive Manufacturing.

In the realm of data science, the ATSAI team generates insights and automates complex processes with tools for LAAM extrusion categorization and image segmentation, as well as research in LAAM layer detection using images and point clouds. Their data engineering efforts focus on improving research data accessibility and transparency through the development of an open-source Material Process-Property Warehouse platform. Additionally, the team works on advancing the Industrial Internet of Things with innovations like the “Smart” ROS2 Data Collection platform, aimed at enabling smarter manufacturing practices.