Work done through the Hub & Spoke program covered in Composites World

Orono, Maine — For years the Advanced Structures and Composites Center (ASCC) has worked with bio-based additive manufacturing technology and materials to create more sustainable feedstocks for small and large-scale additive manufacturing. Through the Hub & Spoke program, the ASCC has closely worked with the Oak Ridge National Laboratory (ORNL) to develop cellulose nanofibrils (CNF) and manufacturing applications for these materials.

The Hub & Spoke Program with Oak Ridge National Laboratory was initiated by the University of Maine’s Advanced Structures and Composites Center in 2016, when officials from Oak Ridge National Laboratory visited Maine as part of the Economic Development Assessment Team (EDAT). Modeled after the National Disaster Recovery Framework, an EDAT enables the federal Economic Development Administration to marshal the full range of federal resources on behalf of a region experiencing economic distress like Maine experienced with the closure of major paper mills, which resulted in the loss of thousands of jobs. The ‘ Hub and Spoke ‘ program combines the Advanced Structures and Composites Center’s extensive forest-derived bio-based composites expertise with Oak Ridge National Laboratory’s advanced manufacturing capabilities through its Manufacturing Demonstration Facility to connect a national laboratory to local ecosystems. Since then, the Hub and Spoke program has grown to include researchers from across the University of Maine, Oak Ridge National Laboratory, and the University of Tennessee Knoxville.

Low-void, large-scale, high-volume 3D-printed composites

HANNAH MASON, Associate Editor, CompositesWorld

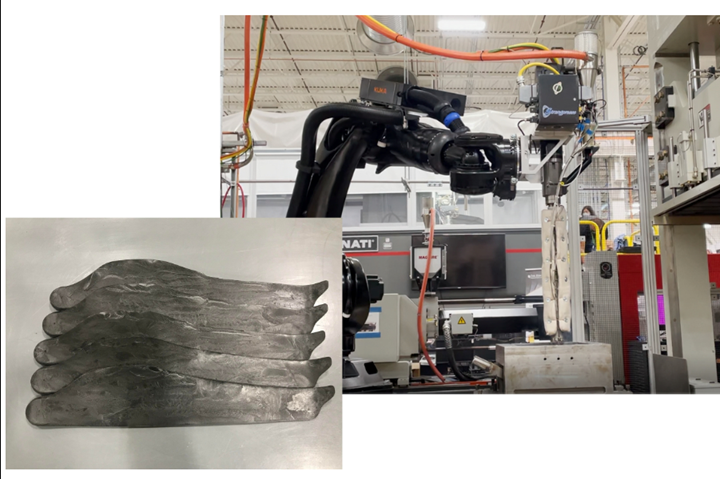

“Bio-based materials development is also a key focus area, especially bio-based feedstock for 3D printing, led by Dr. Soydan Ozcan, senior R&D scientist at ORNL. ORNL partners closely with the University of Maine Advanced Structures and Composites Center (UMaine, Orono, Maine, U.S.) on the development of cellulose nanofibrils (CNF) and applications of these materials using a variety of manufacturing processes. In one pilot project with UMaine, two molds for seven-piece, 100-foot offshore wind blades were built on UMaine’s 60- x 22-foot build volume LFAM printer using CNF materials. Within this project, ORNL completed the materials and equipment development.

Another team, focused on sustainability, is conducting work on lab-scale recycling methods for composite components including wind blades. The system here employs a shredder and waterjet cutter to explore new ways of processing/shredding end-of-life (EOL) parts. Reuse cases are also being evaluated, such as incorporating recycled chopped material into 3D printing pellets to feed back into the BAAM printer.”

Low-void, large-scale, high-volume 3D-printed composites

Composites World

Contact: Taylor Ward, taylor.ward@maine.edu