UMaine Students Spent the Summer Interning at NASA

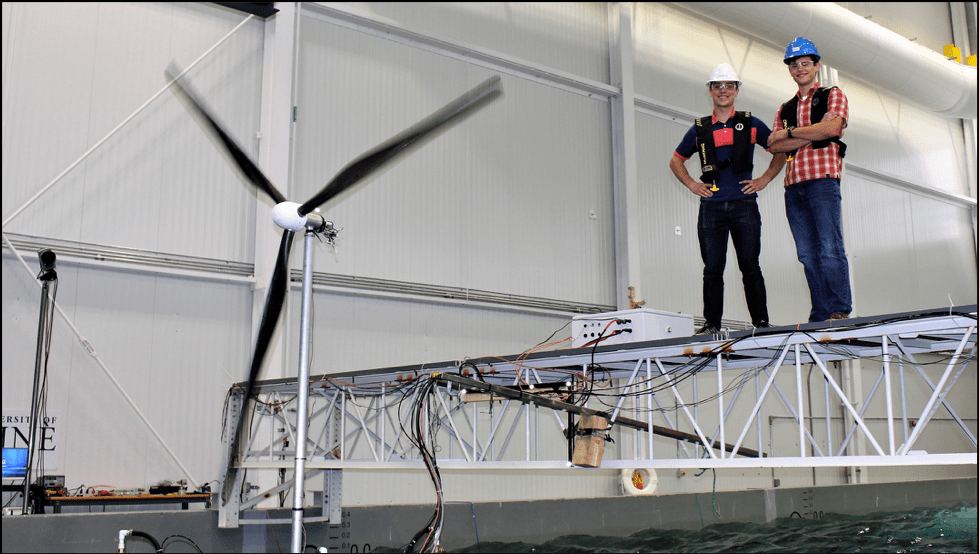

Eben Lenfest and William Ramsay, mechanical engineering students from the Advanced Structures and Composites Center, interned at NASA over this past summer. They acted as the two design leads on a project regarding a new model of offshore wind turbines.

Eben and William have been working for the past ten months on improving the VolturnUS, a floating offshore wind turbine. They used a new technology to increase the longevity of floating wind turbine platforms.

“We’re trying to reduce the up-and-down vertical motion of the wind platform. . . so that you get more years of service out of a platform,” Lenfest said. This will reduce the amount of maintenance needed on a platform and lower its lifetime project costs.

NASA was impressed enough with Eben’s and William’s work that the two students were invited to the NASA Marshall Space Flight Center for the summer.

“At first, [I thought] ‘Wow, this is kinda ridiculous,’” Eben said. “I was just surprised overall, but really excited. . . It made me happy to know that somebody down at NASA that hadn’t met me had enough faith in me to be able to take this on.”

Similarly to Eben, William was grateful and excited for his internship.

“I was thrilled,” William said. “It was the opportunity see a part of the country I’d never been [Alabama], be in the same place where engineers designed the rocket that brought Americans to the moon, and meet and learn from some incredible engineers.”

During his internship, Eben was responsible for deciding how the technology would be attached to a turbine by using a series of equations to size the model. Additionally, Eben analyzed data regarding how the turbine was affected by the technology and potential environmental conditions.

“We did have a lot [of help,] both at NASA and from the Composites Center,” Eben explained in regards to the difficulty of his work. “We spent a lot of time talking to a few of the people who are the pioneers of this technology, trying to figure out what equations we need to size [the model].”

While William also assisted in determining how the technology was implemented, his specific responsibilities involved him performing tests and making changes to the model he and Eben were constructing.

“As an intern, it was my job to come up with a design to apply the concepts of this technology within the design constraints of a 1/50 scale VolturnUS for a proof of concept test,” William explained. “As it turned out, this was not a straightforward task, so it took a lot of hands-on testing and troubleshooting here at the NASA Marshall Space Flight Center to come up with a working design.”

According to William, another goal of their project was to create a model to prove their improved turbine would operate effectively in a marine environment.

“Over the summer [at the NASA Marshall Space Flight Center], we designed and developed this technology so that we could apply it to the VolturnUS and build a 1:50 scale proof of concept,” said Ramsay. “The end goal is that we can show the maritime industries how this technology can be used.”

While William has decided to remain at the NASA Marshall Space Flight Center, Eben has returned to UMaine to complete his education and continue working at the Composites Center.