UMaine engineers make waves in naval architecture

A tiny storm rages at the University of Maine’s Advanced Structures and Composites Center.

Simulated wind and waves beat against the hull of a model FPSO vessel in conditions comparable to a 100-year storm off the coast of western Africa.

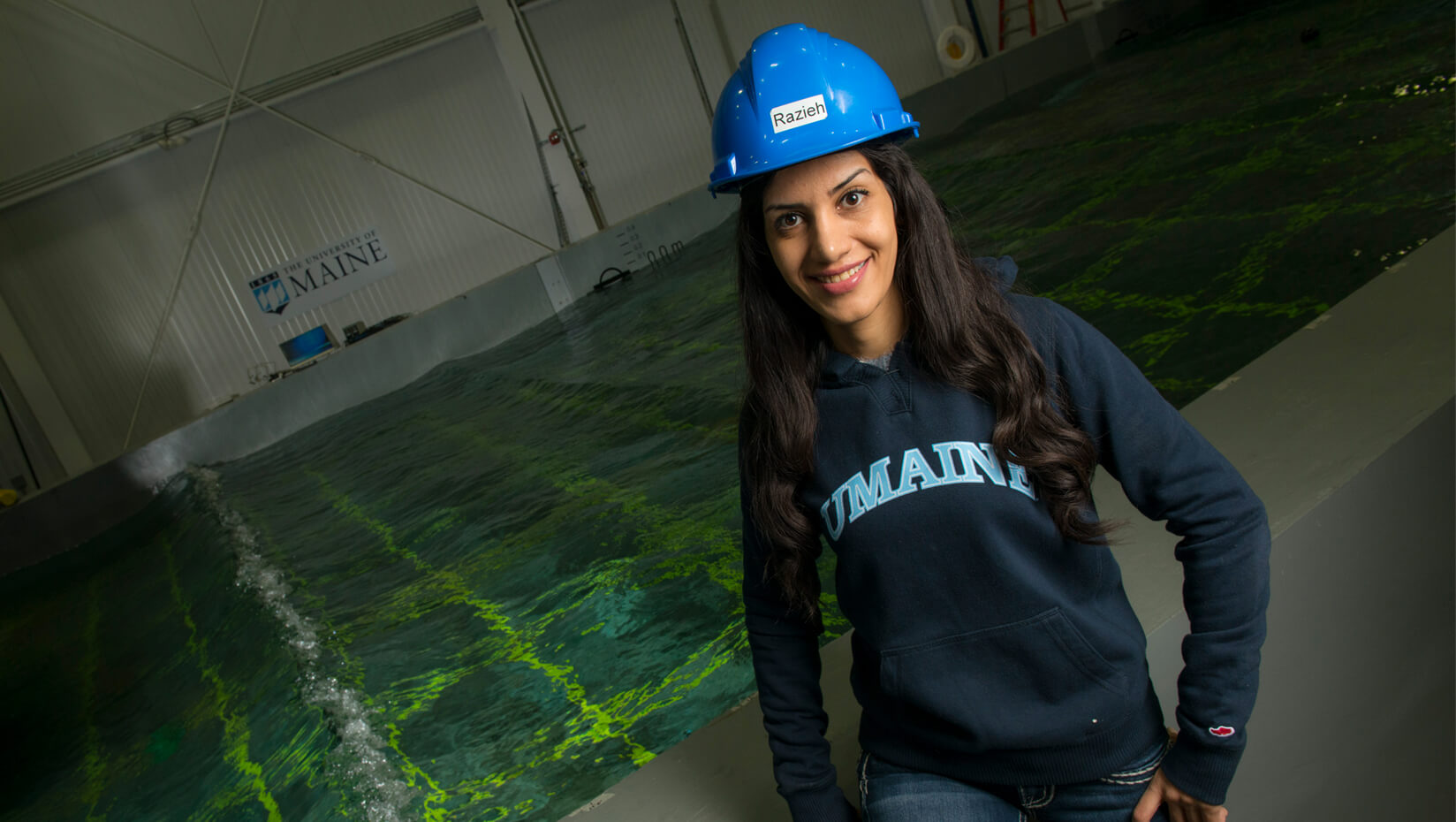

Watching from the side of the wind-wave basin in the Alfond W2 Ocean Engineering Laboratory, Razieh Zangeneh, a UMaine Ph.D. student in mechanical engineering, closely monitors the three-meter-long model’s movement as it rises and falls over the swells.

Floating Production, Storage and Offloading vessels, also known as FPSOs, have become a primary method for extracting, processing and storing offshore oil and gas in many areas around the world. Hydrocarbons from beneath the seafloor are transported to the vessel through a network of undersea pipelines and wells. Once onboard, the oil is processed and stored until it can be offloaded onto small shuttle tankers and transported to coastal refineries.

The floating production vessels are often retrofitted oil tankers. However, unlike their mobile counterparts, they are permanently moored to the sea floor for long periods of time. As a result, they endure a wide variety of ocean conditions, including extreme storms.

Zangeneh, who came to UMaine after finishing a master’s degree at the Amirkabir University of Technology in Tehran, Iran, is studying the performance of FPSO hull shapes and the deep-water mooring systems that hold them in place in offshore environments, where two different wave systems moving in uncorrelated directions — or bidirectional waves — combine with wind to produce complex ocean conditions.

FPSO vessels are commonly held stationary by a turret mooring system, which is attached to the hull at or near the bow of the ship. It allows the vessel to freely swivel, or weathervane, in response to the prevailing ocean conditions, keeping the vessel’s bow pointed into oncoming wind and waves. This orientation helps reduce the strain on the mooring system, production equipment and crew during heavy seas and storm events.

However, in some parts of the world, local wave systems and wind combine with swells borne from distant ocean storms and produce bidirectional wave patterns. These patterns have been shown to cause heading instability in moored FPSOs, which can have a tremendous impact on the stability of the vessel.

The wind-wave basin at the Alfond W2 Ocean Engineering Lab is one of the few facilities in the world that can model both wind and bidirectional wave patterns and simulate some of the worst and most dynamic ocean conditions on the planet.

The 1/120-scale FPSO hull was built at the UMaine Marine Ocean and Offshore Research (MOOR) Laboratory with help from graduate and undergraduate mechanical engineering students. While the model is just over 9 feet in length, it represents a ship more than 1,000 feet long, 190 feet tall and weighing 3,000 tons.

The 100-year storm conditions in the waters off western Africa, while relatively tame compared to other regions of the world, are often comprised of long-period swells and local waves with varying degrees of severity and direction, combined with sudden changes in wind speed and direction. The area is home to a growing number of FPSO vessels.

“FPSO mooring systems should be designed for the different environmental conditions they will be used in,” says Zangeneh, adding that the data they’re generating at the Alfond W2 Ocean Engineering Lab will be very useful in informing these designs. She also is testing the model in the more extreme storm conditions of the Campos Basin, another deepwater oil reserve off the coast of Brazil.

Zangeneh’s research is helping to verify and validate the simulation and testing capacity of the Alfond W2Ocean Engineering Lab.

“The W2 data is in great agreement with computational models and other scale model experiments at other facilities around the world,” says Krish Thiagarajan, Presidential Chair in Energy, professor of mechanical engineering and Zangeneh’s academic adviser.

“I really can’t think of any other facility in the world like the one we have here at the University of Maine,” says Thiagarajan.

Thiagarajan leads the MOOR group and works with students researching how human-made structures interact with the complex, and often chaotic, ocean environment. Their focus spans offshore wind and wave energy systems, coastal infrastructure and naval architecture.

Zangeneh’s research is helping to open the door for future collaboration between the University of Maine and the offshore oil and gas industry, and her work has already gained the attention of commercial and naval shipbuilders.

Zangeneh and the MOOR research group are currently working with General Dynamics Bath Iron Works (BIW) to test a U.S. Navy Combatant model. The model DTMB 5415 hull will be built at the UMaine Composites Center and tested on the lab’s soon to be implemented tow carriage.

“The primary goals of this project are to foster a working relationship between the Advanced Structures and Composites Center and BIW as well as to further validate the testing capacity of the Alfond W2 Ocean Engineering Lab,” says Zangeneh.

Zangeneh says that the lab is capable of providing unique research opportunities for Maine’s shipbuilding industry as well as for the many undergraduate and graduate students that work at the facility.

Contact: Walter Beckwith, 581.3729