Facilities

Facilities &

Capabilities

World-class Research, Innovation & Facilities

Maine’s Largest

University Research Center

The Advanced Structures and Composites Center is a world-leading, interdisciplinary center for research, education, and economic development encompassing material sciences, manufacturing, and the engineering of composites and structures. The Center is housed in a 100,000 ft2 ISO 17025-accredited testing laboratory.

Join Our Team

Interested in learning more about career opportunities at the ASCC?

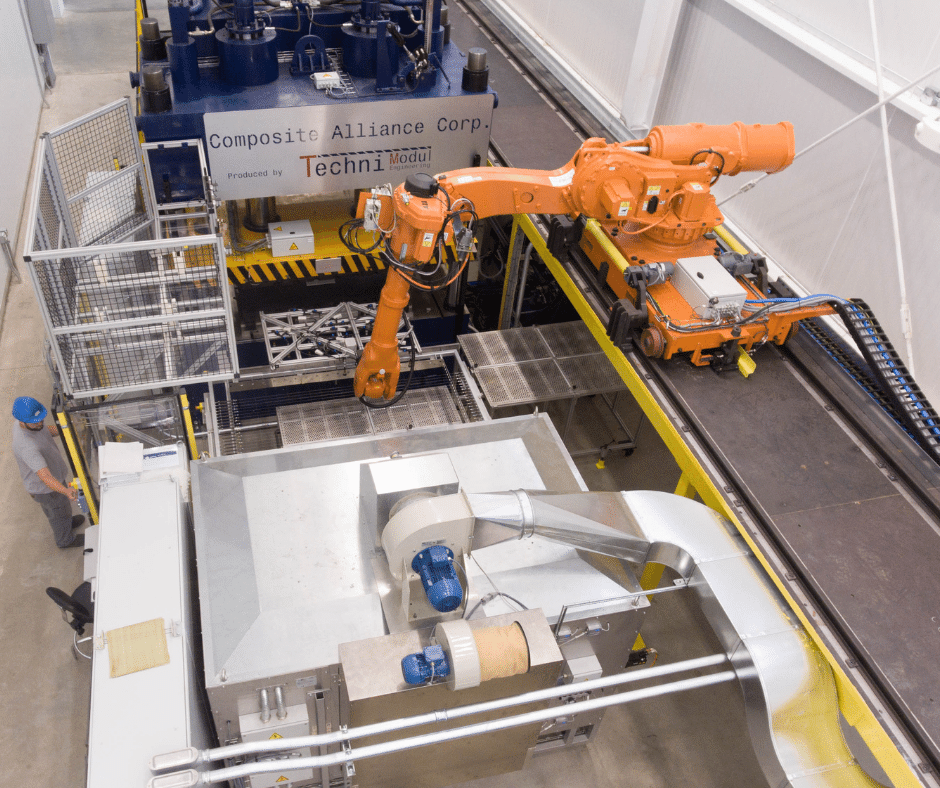

Alfond Advanced Manufacturing Lab for Strucutal Thermoplastics

Instrumentation in the Structural Testing Lab

Alfond W2 Ocean Engineering Lab

Wood Pilot Line

Structural Testing in the Offshore Wind Lab

Structural Testing Lab

Alfond Advanced Manufacturing Lab for Strucutal Thermoplastics

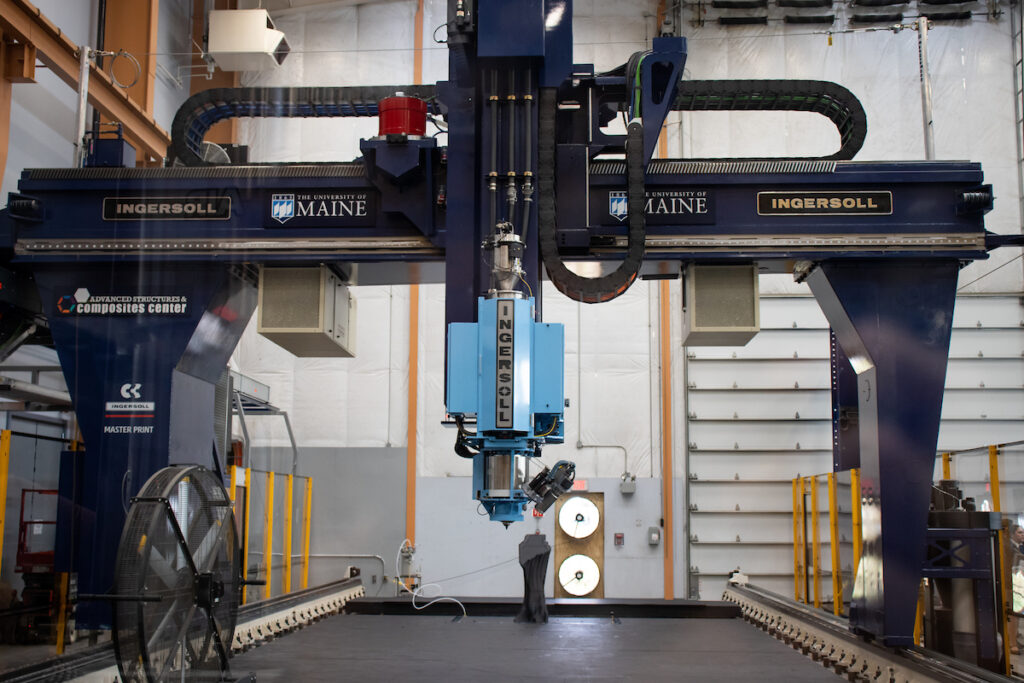

Additive Manufacturing

World’s Largest Polymer 3D Printer

Wood Testing in the Structural Testing Lab

Alfond W2 Ocean Engineering Lab

Wood Composite Testing