Project Summary: Hybrid Thermoplastic Composite-Concrete Beam with Welded Shear Studs

Project Summary

The Engineering Research and Development Center (ERDC) of the U.S. Army Corps of Engineers works with the Advanced Structures and Composites Center (ASCC) at the University of Maine on a variety of projects. Task two focuses on using thermoplastic materials for the development of a stiffened panel system for use in load bearing hybrid composite-concrete structures. Two graduate students Camerin M. Seigars (B.S. Mechanical Engineering) and Benjamin T. Smith (B.S. Civil Engineering) work together on this project as they work toward their master’s degrees with Prof. William Davids and Prof. Roberto Lopez-Anido as co-advisors.

The initial phase of this project was a literature review of thermoplastics and their variety of advantages in structural applications including recyclability, corrosion resistance, amenability to rapid manufacturing, impact resistance and high strength-to-weight ratio. The next phase was material characterization of two thermoplastic materials to build a basis for material selection for component-level specimens. Characterization was done with two thermoplastic materials: Elium acrylic, a two-part liquid thermoplastic resin, and polyethylene terephthalate glycol (PETg) prepreg tapes. Both materials are used with E-glass reinforcing fibers. Elium composites are fabricated in a vacuum infusion process similar to what is traditionally done with thermosets, whereas PETg composites, in this study, are formed through heated consolidation of prepreg tapes.

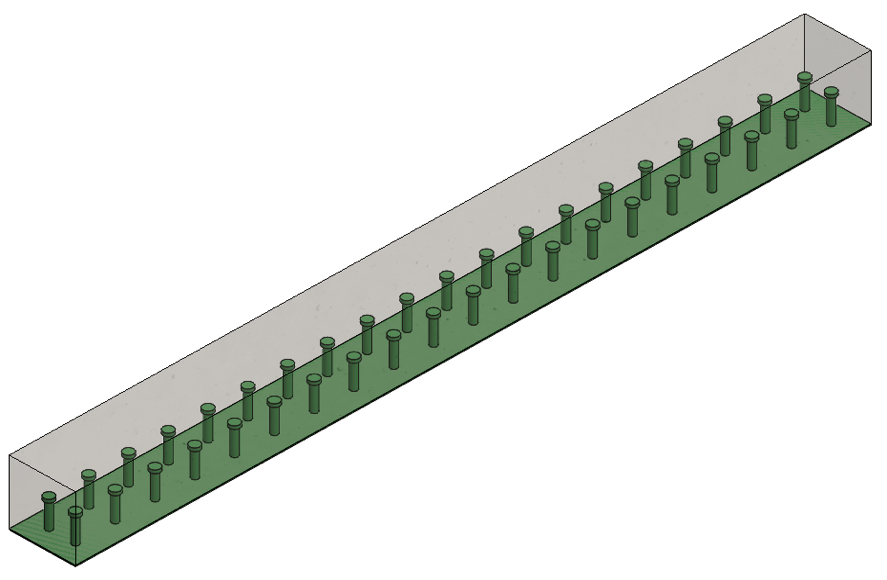

The initial component-level specimens will be hybrid composite-concrete beams as shown in Figure 1. The thermoplastic composite reinforcement in the initial design is PETg reinforced with E-glass fibers, which is used as tensile reinforcement in the beam. Shear is mechanically transferred between the composite and the concrete by thermoplastic shear studs with a T-hat shape. The studs are bonded to the beam by spin-welding (friction welding). The use of thermoplastics in both the tensile reinforcement and the shear studs allows utilization of the formability of the material, which is not possible with thermosets. The initial test of this application will be conducted on 5-ft long beams of the style shown in Figure 1, which will be tested in four-point bending.

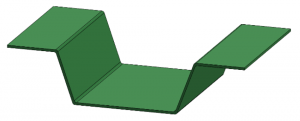

Once the proof of concept is complete for this hybrid beam, more complex cross-sections will be investigated that take advantage of the ability to thermoform thermoplastic plates. Figure 2 shows an initial shape that is being developed. Corrugations are added to increase the flexural stiffness and strength of the plate so it can withstand dead loads before the concrete has cured and serve as a stay-in-place form for the concrete. This process of using hybrid composite-concrete structures can be extended to other applications beyond beams such as bridge decking, retaining walls, and columns.